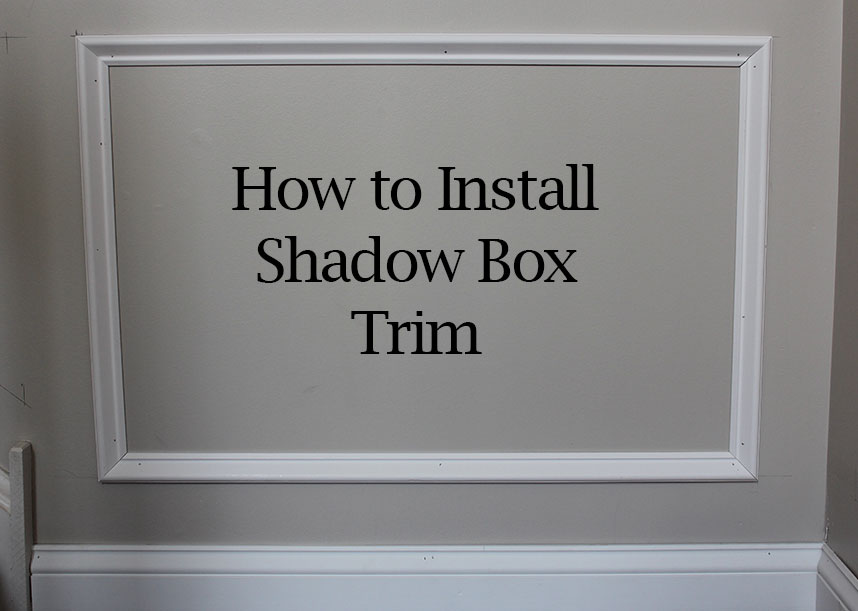

In today’s post, you’ll learn – How to Install Shadow Box Trim It’s been a while since we’ve finished any home improvement projects and although, this latest one is pretty quick and simple, it feels great to wrap up another project nonetheless. Lisa and I had been planning on adding some sort of decor or […]

In this video and post, you’ll learn – How to install chair rail molding – How to install molding on a stairway – How to add end caps to your trim work – How to use two basic tools to figure out what angle to cut your trim pieces to Happy weekend everybody! This past […]

In this video, you’ll learn: – How to remove baseboard molding – How to install new baseboard molding – How to work without a tape measure Well, we finally started our latest home improvement project. As we mentioned a few weeks ago, we’re working towards adding some character in our vestibule with taller baseboard molding, […]

The last couple months have been super busy. In case you couldn’t tell by my complete lack of posting, I haven’t done a whole lot of home improvement work lately. Life with three little kids is much more time consuming than it was with two and my free time is just about gone nowadays. I […]

I’m relieved to finally tell you that all of the crown molding has been installed in our home office. It was a bear. Granted, I still have to putty all the nail holes, caulk the joints and paint them. I’ll save that work for the weekend. That’s not the end of the molding in the […]

Hey all! Hope everyone is doing well. Had another productive weekend around here. We got a huge jump on our Pinterest Challenge project. Stay tuned for that! We posted a couple hint photos on our Instagram account. Last week, we wrapped up our sitting room built-in. I also promised a quick post on how to […]

Finally. We’re done the dining room wainscoting project. Yep. All done. Well, except for some minor paint touch ups and a little bit of caulking. BUT, it’s on a 6″ section of doorway baseboard molding, so.. technically, it’s not really IN the dining room. So, like I said. We’re done. High five. I don’t want […]

I was originally thinking about skipping all the posts on our dining room wainscoting until we were completely finished with it. Staged and all. However, it may be another week until it’s all buttoned back up, so I think I’ll just get on with it and show everyone where we’re at. The last couple weeks […]

Hope everyone had a great weekend! Lisa and I were upstate in NEPA on Friday for an annual golf tournament that’s held in memory of my father. It’s usually a great time and the proceeds are donated to a local charity. This was the fifth year we’ve had it. The tournament is organized and run […]

I think this is going to be the last progress post I write on the wainscoting until we’re finished. I’ll probably do one more post on how we replaced the window sill, but that will be it. We’re that close. Over the weekend we were finally able to prime the panels. Instead of brushing on […]