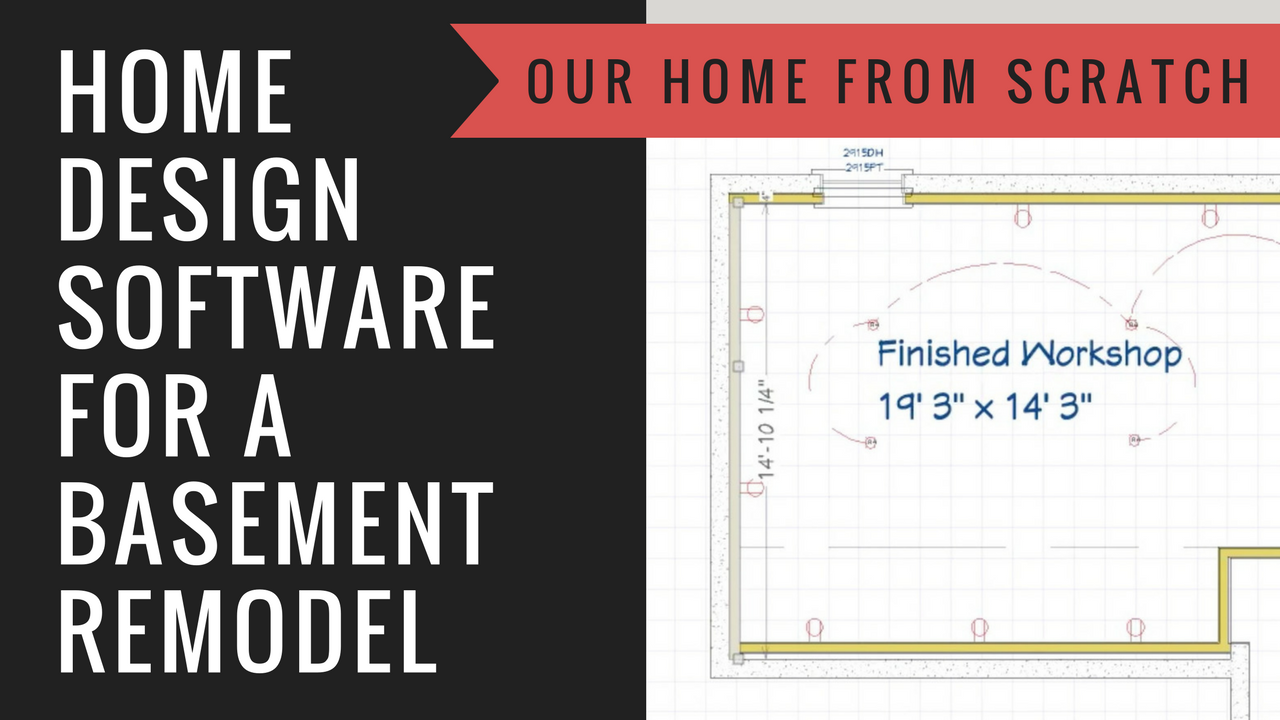

In this blog post, you’ll learn how to design a finished basement prior to a remodel and how to use Home Designer software to help you come up with a great design. Whether you’re planning to remodel your basement yourself or to hire a contractor to do it for you, you’re going to need a design […]

In today’s post, I’m going to tell you how you can get free kitchen cabinet plans to download. Last year I started a new video course to help DIYers design and build their own kitchen cabinets and custom built-in projects. That video course is called “Cabinets from Scratch” and you can check it out at […]

In this video, you’ll learn: – How to remove baseboard molding – How to install new baseboard molding – How to work without a tape measure Well, we finally started our latest home improvement project. As we mentioned a few weeks ago, we’re working towards adding some character in our vestibule with taller baseboard molding, […]

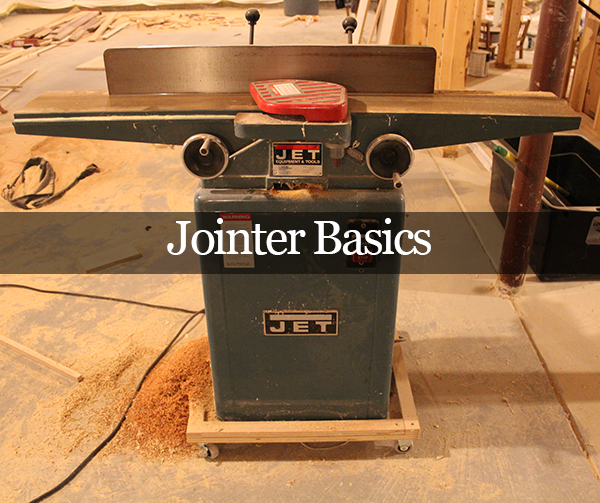

In this post, you’ll learn: – About jointers – How to use a jointer for tighter seams in your projects If you’re just getting started with some basic woodworking projects, you may have heard about or seen a jointer. While it’s not terribly common for DIYers to own one, it’s a pretty useful tool to […]

In this post, you’ll learn all about – Cabinet door hinges – Cabinet drawer slides – What you need to consider when selecting this type of hardware After nearly a year of part time work, our home office remodel is finally finished. Stop back on Wednesday and you’ll get a close up of our newly […]

In today’s post, you’ll learn: – How to make built-in cabinets – How to make a beaded face frame – What the build process for a cabinet looks like After spending the better part of a week and a half painting our home office, I’m finally down to the last couple of detail jobs. Although […]

In this post, you’ll learn – How to build shaker cabinet doors with a router – How to inset the doors into a face frame for a high end look If you’ve been reading this blog for a while, then you’ve probably seen me write about building shaker cabinet doors before. I’ve built them for […]

I’m relieved to finally tell you that all of the crown molding has been installed in our home office. It was a bear. Granted, I still have to putty all the nail holes, caulk the joints and paint them. I’ll save that work for the weekend. That’s not the end of the molding in the […]

Hey gang! Hope everyone had a great weekend! We made some major headway on our built-in project this past weekend. I’ve got the doors finished and the plywood for the boxes all cut. All I’ve got left to do is machine the plywood with some grooves and dados and we’ll be assembling it. So far […]

Hey guys! Hope everyone is enjoying the week so far. If you’re in the Northeast like us, I hope you’re surviving the worst week and a half of weather I’ve ever seen in November, ever. Terrible! Have I ever told you how much I hate the cold? I used to love it when I was […]